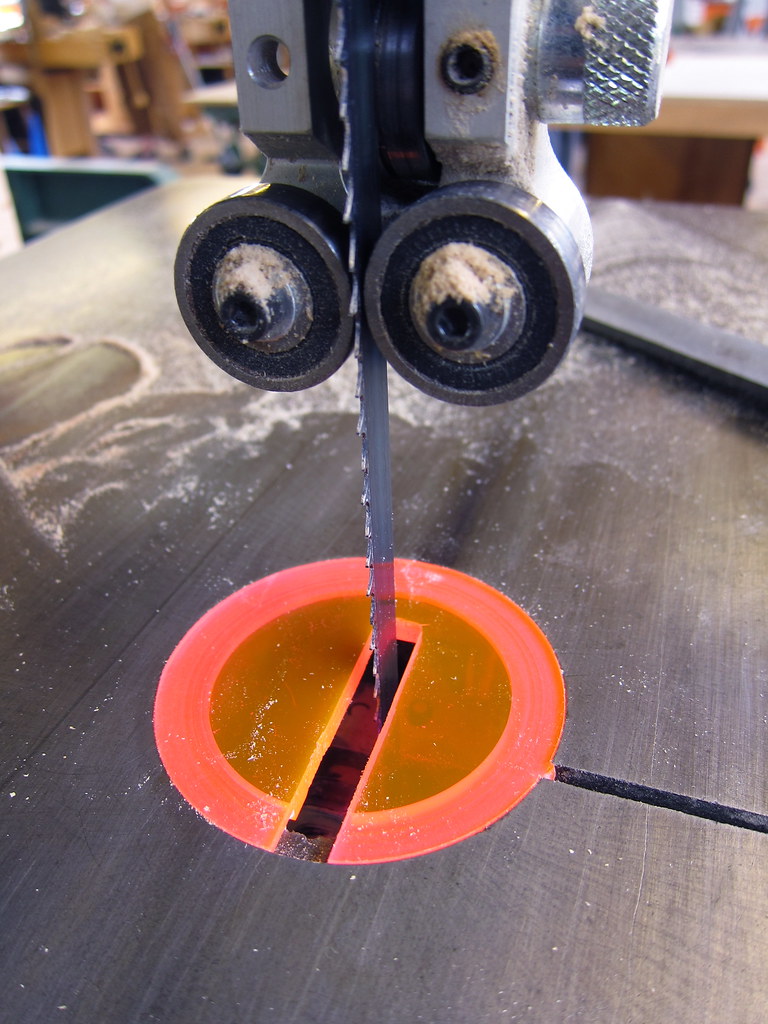

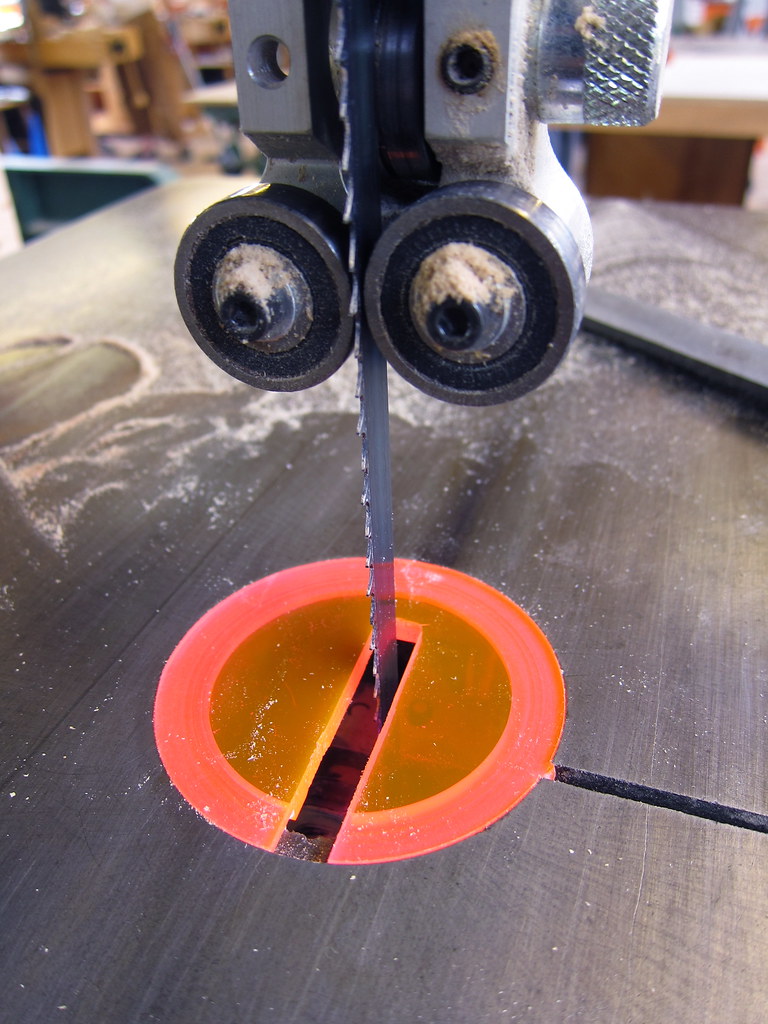

A bandsaw is a highly versatile cutting tool, renowned for its capability to handle a variety of materials, including wood, metal, and plastic. It utilizes a long, continuous loop of toothed metal blade running on rotating wheels, enabling precise and uniform cuts.

Bandsaws are favored for several advantages:

Most bandsaws feature two wheels rotating in the same plane, with one wheel powered. Larger bandsaws might use benching to handle operational forces and heating, requiring regular maintenance. For those getting started, understanding basic concepts like how to make cabinets can be a good foundation.

Bandsaw blades come in various designs, each optimized for specific tasks:

Bandsaws are categorized based on their specific applications:

Feed mechanisms in bandsaws help in material progression during cutting. They include:

Fall mechanisms define the movement pattern of the saw during operation:

Automatic bandsaws enhance operational efficiency with preset feed rates, automated part feeding, and clamping, making them ideal for high-volume production environments.

The choice of bandsaw largely depends on the user's needs:

| Blade Type | Description | Ideal Use |

|---|---|---|

| Regular Tooth Blades | Straight, evenly spaced teeth | General-purpose cutting in wood, plastic, thin metals |

| Hook-Tooth Blades | Larger teeth with positive rake angle | Fast cutting in thicker materials |

| Skip-Tooth Blades | Widely spaced teeth with shallow gullets | Clean cuts in delicate materials and softwoods |

For more specific tasks, products like the 37" Replacement Diamond Coated Band Saw Blade are ideal for precise cutting needs.

Regular maintenance and safety practices are paramount for bandsaw usage:

Bandsaws are indispensable tools in both hobbyist and industrial settings, offering unparalleled versatility and precision cutting capabilities. Whether cutting intricate curves or resawing thick lumber, understanding the various bandsaw types and their applications allows users to maximize their efficiency and achieve superior results. For high-volume and efficient lumber production, referring to resources like Efficient Use of Bandsaws in Lumber Manufacturing can be highly beneficial for further insights.

Additionally, for heavy-duty metal cutting applications, checking out the JET 16-Inch Vertical Metal Bandsaw can provide a robust solution. Lastly, for an all-around general-purpose blade, the Starrett Duratec SFB Band Saw Blade is a reliable option.

Immerse yourself in architecture’s most boundary-pushing ideas—where innovative home improvements meet visionary urban developments. Discover new building techniques, materials, and creative concepts that are redefining how we shape our spaces on a global scale.