If you’ve ever worked with a table saw, you’ve likely come across the term "rip capacity." Understanding what rip capacity means and how it affects your woodworking tasks is essential for making the most out of your table saw. This post delves into the details of rip capacity, its significance, variations in different table saws, and tips for optimizing it.

Definition and Importance

Rip capacity refers to the maximum distance between the fence’s edge and the blade when the blade is extended. This measurement determines how wide a piece of wood can be ripped (cut along its grain). Understanding rip capacity is crucial for anyone using a table saw, as it directly influences cutting efficiency and the scope of projects you can undertake. For detailed comparisons between different saws, check out Table Saw vs Circular Saw: Choosing the Right Tool for You.

Variations in Rip Capacities

Different types of table saws come with varied rip capacities. Here’s a comparison of typical rip capacities across different saw types:

| Table Saw Type | Rip Capacity | Ideal For |

|---|---|---|

| Portable Table Saws | Up to 28 inches | Entry-level tasks and standard craftsman jobs |

| Contractor Table Saws | About 30 inches | Most standard cuts, preferred by contractors |

| Professional Cabinet Table Saws | Up to 50 inches | Heavy-duty jobs and professional woodworkers |

| Hybrid Table Saws | Varies, typically between 30-40 inches | Good balance for limited space |

Choosing the Right Rip Capacity

Selecting the right rip capacity depends on the complexity and size of your projects. For example:

- A 24-inch rip capacity may be sufficient for framing jobs.

- Smaller furniture projects can be managed with capacities less than 30 inches.

- Larger, intricate projects might require capacities upwards of 50 inches.

Factors Influencing Table Saw Prices

Rip capacity is a significant factor affecting the price of a table saw. Generally, larger rip capacities command higher prices. By closely evaluating your project needs, you can make more cost-effective tool purchases. For more advice on accurate wood cutting, see How to Cut a Hole in Wood Perfectly Every Time.

Methods to Increase Rip Capacity

If your table saw's rip capacity is limiting your work, consider the following methods to increase it:

- Attach a table extension to one side of the saw to increase the rip capacity.

- Adjust or upgrade the existing fence and railings for better rip capacity. Consider using adjustable fence brackets designed to fit your table saw model.

- Purchase ready-made table extensions designed for specific saw models for easy assembly.

Increasing Table Saw Rip Capacity For Free - 179

Difference Between Rip Capacity and Depth Capacity

While rip capacity involves width cuts, depth capacity refers to how deep a blade can cut into wood. Both are crucial for achieving quality rips and ensuring your cuts are well-executed. For essential information, see Cabinet saw...Is wide rip capacity all that important?.

Safety Considerations

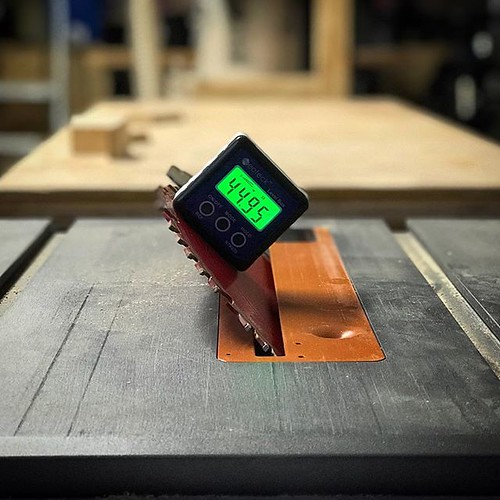

Proper setup and adjustment of your table saw are pivotal for safety. Ensure that:

- The fence is securely set to prevent wood from shifting during cuts.

- The blade depth is correctly adjusted to protrude slightly above the wood surface.

- You use a push stick to maintain safe distance when feeding wood into the blade.

Guidelines for Ripping Wood

To enhance ripping efficiency and safety, follow these steps:

- Always mark the workpiece accurately for precise cuts.

- Set the blade depth slightly above the wood surface to avoid excessive protrusion.

- Use a push stick especially when dealing with narrow pieces of wood. If you need precise alignment in your cuts, utilize tools like the Peachtree Woodworking Supply PALS Precision Alignment system.

Understanding rip capacity and its implications on your woodworking tasks can greatly enhance your efficiency and the quality of your work. By choosing the right table saw and optimizing its rip capacity, you can tackle a wider range of projects with increased confidence and precision.