Have you ever wondered why there are holes in the prongs of your electrical plugs? These small design elements do more than you might think. Let’s dive into their history, purpose, and the clever engineering behind them.

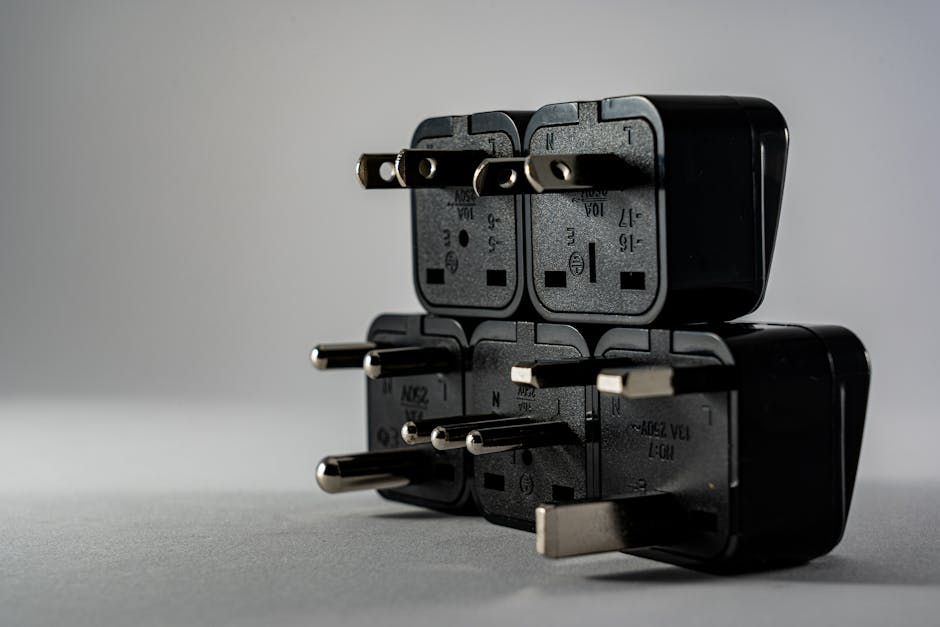

In North America, there are two main types of plugs:

The small holes found near the tips of the flat prongs serve several important functions:

For a detailed explanation on modern uses of these design features, visit Why do Electric Plugs Have Holes? | Third Taxing District.

The concept of holes in electrical plug prongs dates back to the early 20th century. Harvey Hubbell Jr. was the first to patent a detachable electric plug in 1904, incorporating prongs with indents designed to align with bumps in sockets.

Older outlets used mechanisms like captive ball bearings and coil springs for a detent effect. Modern outlets usually rely on bumps and springy copper contacts, but the principle remains similar.

The holes in prongs also serve important roles during the manufacturing process:

| Function | Description |

|---|---|

| Enhanced Grip | Bumps in the socket align with holes to provide a stable connection. |

| Improved Electrical Contact | Ensures a better power connection by stabilizing the plug. |

| Factory Sealing | Plastic ties prevent usage until specific conditions are met. |

| Manufacturing Stability | Rods lock prongs in place during plastic encasing. |

| Cautionary Messaging | Visible warnings threaded through prong holes. |

These holes may go unnoticed by most, but they represent a clever and multifunctional piece of engineering. From enhanced grip to manufacturing stability, the humble prong holes are proof that even small design details can have a big impact on functionality and safety.